The Seven Pitfalls of Whole Slide Scanning

Introduction

The practice of pathology is entering a period of broad adoption of digital workflows, as near real-time access to “digital slides” offers opportunities to greatly improve clinical outcomes and accelerate research. As Liron Pantanowitz, Professor of Pathology and Biomedical Informatics at University of Pittsburgh Medical Center recently described, digital pathology offers benefits with respect to image analysis, education, telepathology, centralized services, archiving, workflow efficiency, subspecialty practice and computational pathology.

The practice of pathology is entering a period of broad adoption of digital workflows, as near real-time access to “digital slides” offers opportunities to greatly improve clinical outcomes and accelerate research. As Liron Pantanowitz, Professor of Pathology and Biomedical Informatics at University of Pittsburgh Medical Center recently described, digital pathology offers benefits with respect to image analysis, education, telepathology, centralized services, archiving, workflow efficiency, subspecialty practice and computational pathology.

However, Pantanowitz also cautions that digital workflows must be executed properly, and this starts with the successful digitization of glass slides by means of whole slide scanning. Get this part right, and it will positively benefit the rest of the pathology workflow.

Let’s look at the seven most prominent pitfalls encountered in whole slide scanning and the potential solutions for overcoming them.

Pitfall #1: Those pesky barcodes

Most slide scanners expect standard 1” x 3” slides to have a single barcode placed at the top of the slide, and are therefore designed to read that barcode in that specific position. But sometimes, multiple barcodes are placed on top of each other, making the slides too thick to fit into the slide handling mechanism. Or, there may be multiple barcodes in multiple locations of the slide. Both these scenarios can result in the need for time consuming manual intervention.

Solution: Find a more accommodating slide holder and image-based barcode capture. Look for a slide scanner that can handle a variance in slide thickness in case there is a need to place a barcode on top of another. The slide holders on Huron Digital Pathology’s TissueScope LE™ scanner, for example, can handle thicker slides. Furthermore, the scanner employs image-based barcode capture, so the barcode or barcodes can be read anywhere on the slide.

Pitfall #2: Trying to scan damaged slides

Through the slide preparation process, slides can become broken or chipped. They can still be scanned, but special care must be taken. The slides may have to be scanned separately, which disrupts the automation expected from digital pathology.

Pitfall #3: Scanners that eat slides

In many scanners, the slide handling mechanism can actually break the glass slide as it moves through the scanner during image acquisition. This not only destroys the slide, but requires scanner maintenance to remove the broken slide and glass. This is clearly a handling hazard for laboratory personnel.

Solution to Pitfalls #2 and #3: Look for a slide holder that does no harm. Choose a scanner that can accommodate imperfect slides without impacting throughput, one that ensures the integrity of the slide. The TissueScope LE120 slide holder has a unique clamping system that can accept slides that are broken or have chips. And because it’s tray-based, the scanner doesn’t actually touch the slides, keeping the precious specimens and fragile glass safe.

Figure 1. The Huron Digital Pathology slide holder keeps slides safe.

Pitfall #4: The care required in slide preparation

Most slide scanners are automatic, generally designed to accommodate pristinely prepared slides with little variability. In reality, this is often not the case. Therefore, extra care needs to be taken by lab staff to reduce the variability in preparation, because this will affect the success of image acquisition, and re-scans are costly to the efficiency of the workflow.

For example, take Canada’s largest microscopy facility, the Advanced Optical Microscope Facility (AOMF) in Toronto. General Manager, James Jonkman and his staff actively instruct those responsible for preparing slides to the facility to adhere to these strict procedures to ensure optimal results:

- Slides are dry and not sticky

- Slides are clean with no finger prints, oil etc. on them

- Labels are not sticky or overhanging the slides

- Coverslips are not overhanging the slides

- No globs of mounting media are on the slides

- No marker annotations such as arrows or circling tissues are on the slides

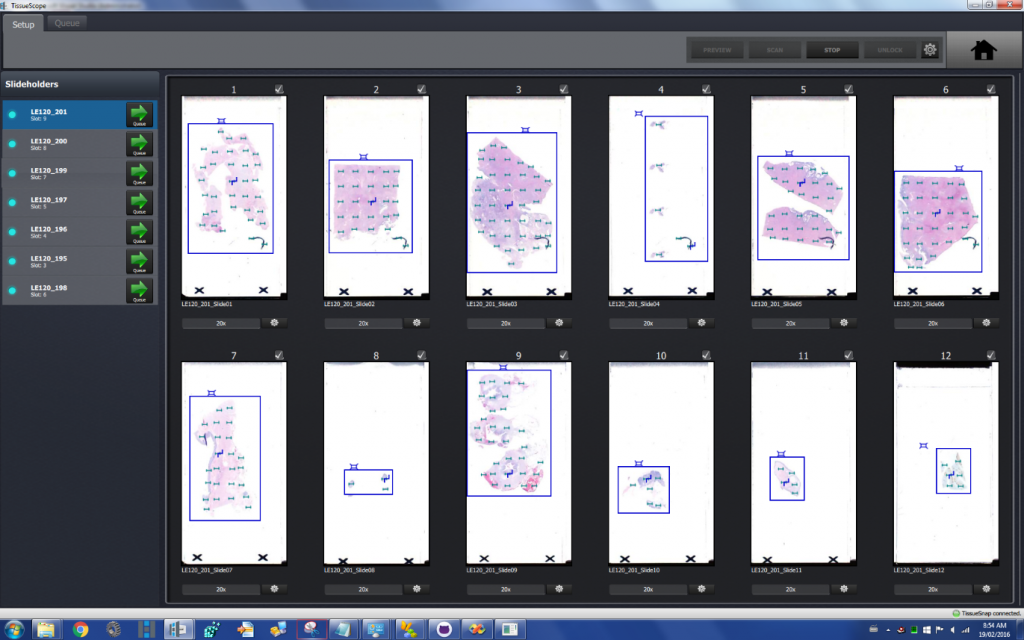

Solution: Find the right slide holder, and take advantage of scan preview. A bit of extra mounting media shouldn’t ruin your day, so look for a scanner that can handle difficult slides without impacting throughput. Also, if available, take advantage of the scanner’s preview function to ensure that the scans are set up to be properly acquired. Make sure your scanner allows for full control of the region of interest, focus area, and other factors to ensure a successful scan.

Figure 2. Huron’s interface gives users more power to tackle difficult slides.

Pitfall #5: Managing scanner down-time

As demonstrated by pitfall #4, scan preview and set-up is a critical step for ensuring all slides are properly imaged. However, this step can be time consuming, costing 10-20% of scanner throughput each day. Instead of acquiring images, your expensive investment (the medium to high throughput slide scanner) sits idle. Further, the power of these cameras is routinely wasted when spent taking low-resolution preview images. So how can digital pathology workflows increase throughput without sacrificing image quality?

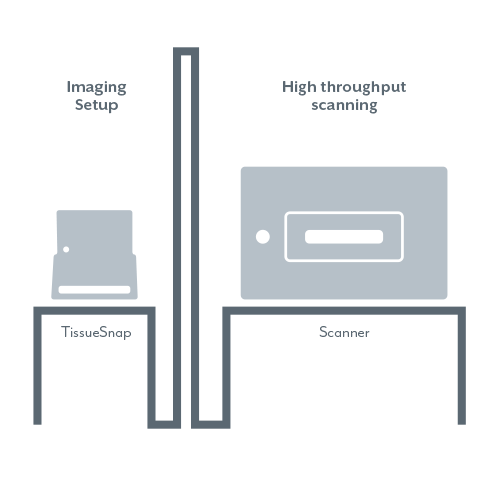

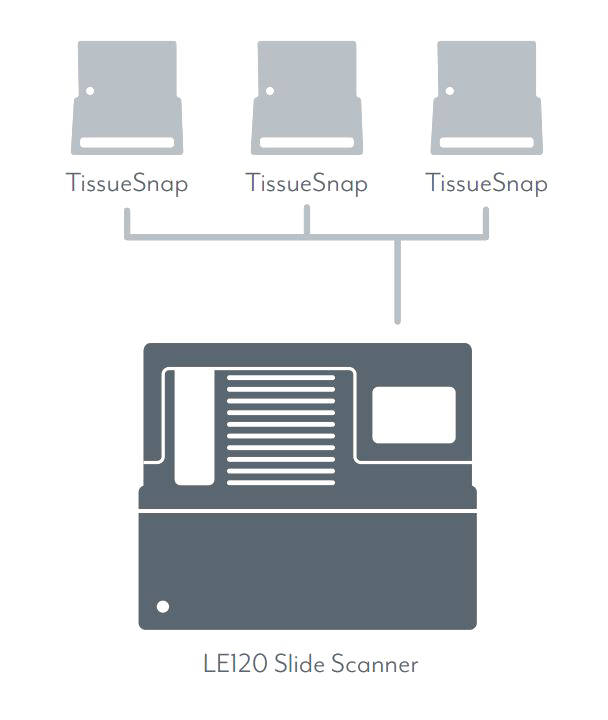

Solution: Improve scanner throughput by offloading scan preview and setup. If a workflow can separate preview acquisition from final image acquisition, the imaging system will be put to best use, maximizing throughput. Huron Digital Pathology’s TissueSnap™, which works along-side the TissueScope LE120, is designed to do just that.

A few words about Huron’s TissueSnap Preview Station

Figure 3. The TissueSnap connects to an LE slide scanner to maximize throughput.

While the TissueScope LE120 is scanning, the TissueSnap can capture preview images of slides yet to be scanned. The preview images are sent instantly to the main scanner’s user interface. As the scanner continues to acquire high-resolution images, the next batch of slides can be previewed and setup simultaneously without interruption.

As well as separating image set-up from high throughput scanning, TissueSnap has a compact size and networkability that mean it can be placed almost anywhere in the laboratory. Various TissueSnap preview stations placed in different locations can feed a single high throughput scanner, thereby improving workflow.

Pitfall #6: Navigating proprietary file formats

Once image acquisition is complete, the digital slide may move through a series of other phases: image viewing, image management, image sharing, and image analysis. As the digital slide travels through this cycle, it may interact with different software systems, which may have varying degrees of integration with image acquisition. For example, the image analysis software may prefer file formats different from that of the viewing software. The risk here is of additional investment in software development, extra expense on proprietary image viewers, or at worst, incompatibility.

Solution: Open up. Look for scanners that output in a non-proprietary file format. TissueScope LE, for example, creates a BigTIFF that can be read by just about every image management and image analysis software, making it fast and simple to integrate. That gives you a lot of freedom to easily mix and match hardware and software components, and reduce cost.

Figure 4. The TissueScope LE120.

Pitfall #7: Slides that are too big

While most slides are standard size (roughly 1” x 3”), there are instances – particularly in the research area – where tissue can be much larger. This is particularly true with whole mount brain, breast, and prostate tissue. So, what do you do about these larger slides?

Solution: Be flexible. Choose a scanning solution that can accommodate multiple slide sizes. Huron’s TissueScope, for example, can accommodate both standard and double-wide slides, and any size slide up to 6” x 8”.

About Huron Digital Pathology

We believe that innovation is the key to making digital pathology a ubiquitous reality. But for us, innovation is about more than just delivering great image quality and fast scanning speeds. It’s also about designing products that are simple to use, easy to integrate with your workflow, and have attractive price-performance characteristics.

Based in Waterloo, Ontario, Canada, Huron Digital Pathology has a 20+ year history designing sophisticated imaging instrumentation. Our end-to-end digital whole slide imaging solutions combine the award winning TissueScope™ digital slide scanner, image management software, and workflow enhancing accessories.

Source: Huron Digital Pathology